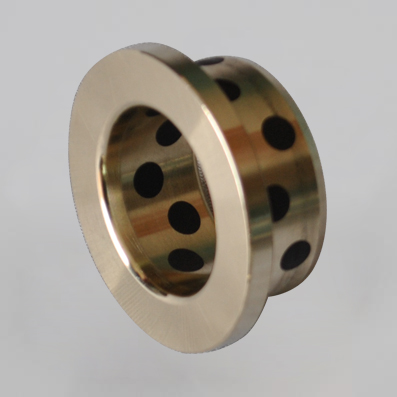

Sliding bearing manufacturing material analysis. A bearing in which a plain bearing operates under sliding friction. The sliding bearing works smoothly, reliably and without noise. Underneath is liquid lubrication, which can be significantly reduced by direct contact and frictional losses of the lubricating oil and wear separation of the surface, and the oil film also has some capacity for absorbing vibration. However, the initial frictional resistance is large. The portion of the shaft that is supported by the bearing is called the journal, and the portion that matches the journal is called the bearing. This is a layer of reduced friction material that is molded on its inner surface to improve the frictional properties of the surface of the pad bearing is referred to as a bearing coating. Sliding bearing applications are typically used in low speed and heavy load conditions, or where it is difficult to maintain and fill the lubricant.

1. Metal materials such as bearing alloys, bronze, aluminum alloys, zinc-based alloys, etc.

Alloy bearings: alloy bearings, also known as white alloys, mainly tin, lead, niobium and other metal alloys, due to their tough type of wear, high plasticity, good running performance, good thermal conductivity, good oil resistance, good The adsorption is suitable for boxes and heavy duty high speed, bearing alloys are low resistance and expensive, and must be cast in bronze, steel or cast iron pads to form a thin layer.

2. Porous metal material (metallurgical powder material)

Porous metal material: The porous metal is a powder material having a porous structure and, if immersed in a lubricating oil, is filled with a lubricating oil hole to have self-lubricating properties with bearing oil. Porous metal materials have low toughness and are only suitable for soft loads, no impact and medium to small speeds.

3. Non-metallic materials.

Plastic plain bearing:Phenolic plastics, nylon, PTFE, and plastic bearings commonly used in plastics have large compressive strength and wear resistance. They can be used for lubrication with water and oil, but also have self-lubricating properties, but have poor thermal conductivity.

Working on plain bearings due to contact between the trunnion and the bearing creates friction, which results in heat, wear and even "death" on the surface, so the design of the bearing should be used to improve the friction material bearing, proper lubricant and use. The correct supply method is used to improve the bearing structure of thick film lubrication.