SPECIAL PLASTIC SLIDING BEARING

- Sel M1

The general-purpose strong plastic bearing can meet most working conditions below 80 working temperature. The excellent wear resistance and economical price are the designer's preferred materials.

1. Adapt to different material axes

2. High abrasion resistance, dust and dirt resistance

3. Continuous use temperature: -40 ° C ~ +130 ° C

4. Suitable for medium to high loads

5. Self-lubricating, suitable for dry running, maintenance free

6. Suitable for rotary motion, swing motion

Bearing TechnologyMaterial Property SheetProduct Size Table Download

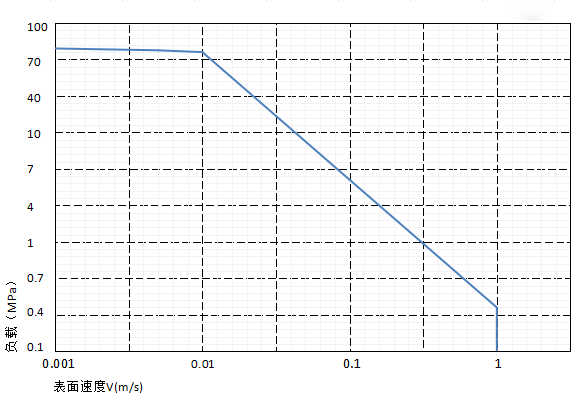

The upper limit of the Seleilte? M1 series engineering plastic bearing has a PV value of 0.5N/mm2*m/s; this determines that the load on the bearing is inversely proportional to the speed. Please refer to the details.

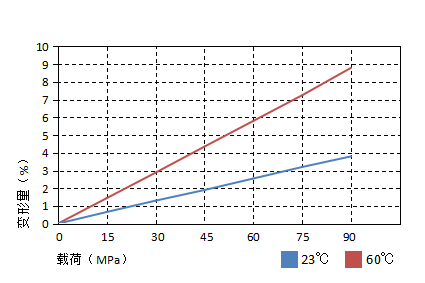

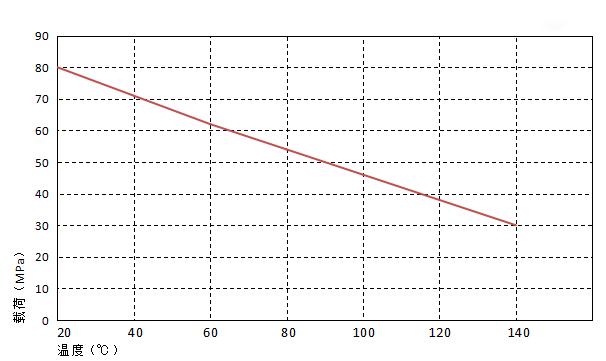

Seleilte? M1 series engineering plastic bearings are tested in the maximum upper limit static load of 90Mpa. Under this load, the upper limit compression deformation of the bearing is referenced. The actual running upper limit load of the bearing must not exceed 80Mpa; the load will also be affected by the running speed and temperature. The faster (Vmax: 1.0m/s) will cause the friction temperature to rise, and the temperature rise (Tmax: 130°C) will cause the bearing capacity of the bearing to gradually weaken, and the load will change with the bearing operating temperature.

load-temperature-deformation chart

load-temperature chart

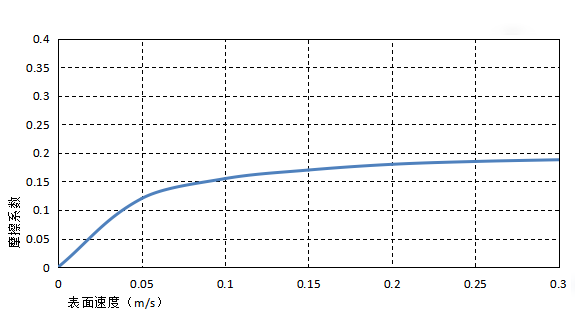

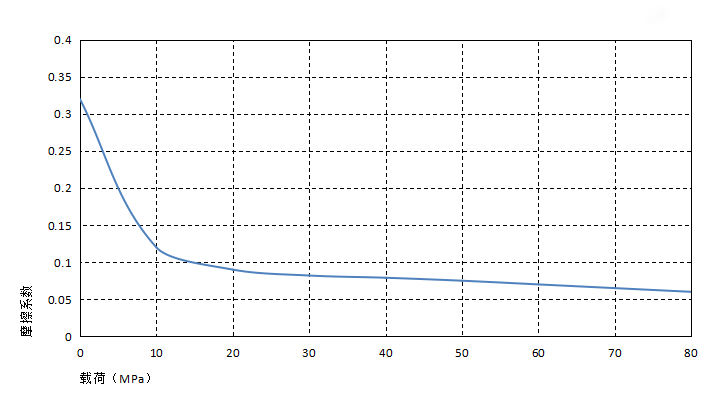

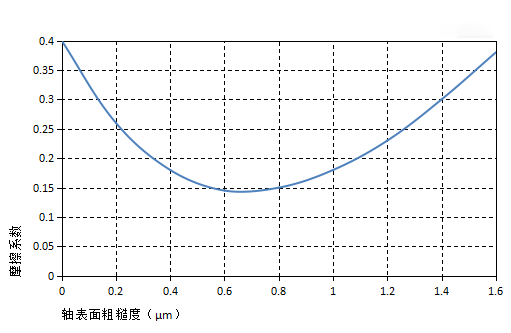

The friction coefficient of Seleilte? M1 series plain bearings is closely related to the load, running speed and surface roughness of the shaft material. The friction coefficient of Seleilte? M1 sliding bearing will increase with the increase of running speed; it will decrease with the increase of load. It also fully demonstrates that the Seleilte? M1 plain bearing is suitable for high load and low speed applications; the smoother or rougher the shaft surface roughness will also lead to an increase in the friction coefficient of the bearing. The surface roughness of the Seleilte? M1 bearing is Ra0.5. ~Ra0.8

| seleilte? M1 | dry running | grease | oil | water |

| coefficient of friction(μ) | 0.08~0.18 | 0.09 | 0.04 | 0.04 |

relationship between friction coefficient and running speed P=2MPa

friction coefficient and load relationship diagram V=0.2m/s

relationship between friction coefficient and shaft surface roughness

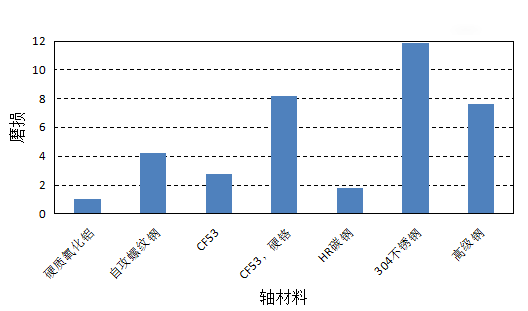

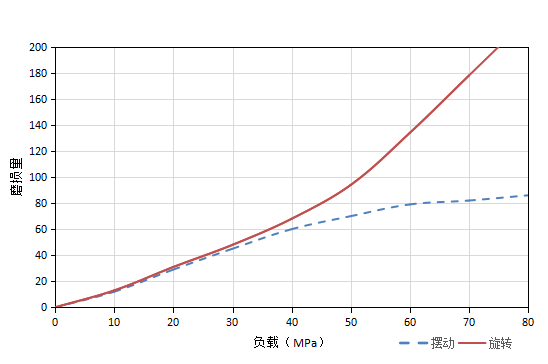

The test data on different shafts shows that the Seleilte? M1 bearing has the best performance on the carbon steel shaft and the hard chrome shaft at low load; the bearing hardness is higher as the bearing load increases; the soft shaft is easier to produce. Wear and tear, resulting in increased bearing wear. When the bearing load exceeds 2 MPa, the wear of the bearing decreases as the shaft hardness increases. The diagram shows that the Seleilte? M1 performs better than the rotary motion under the oscillating motion. Under the same working conditions, the wear under the oscillating motion is smaller than that of the rotary motion, especially under high load.

relationship between wear amount and material change of different shafts P=2MPa V=0.2m/s

relationship between wear and load and rotation under swing and swing operation

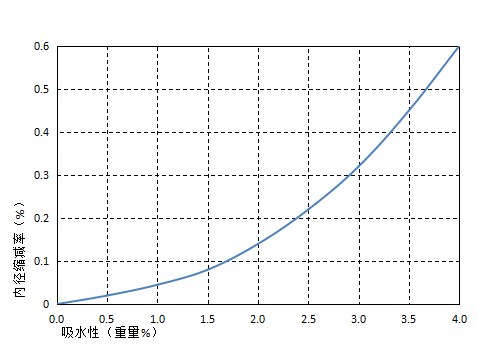

In standard atmospheric pressure, the water absorption of the Seleilte? M1 plastic bearing is 0.7%, and the upper limit water absorption in the soaking water is 4.0%; therefore, due to the water absorption characteristics, the application environment of the bearing must be considered.

Seleilte? M1 will not change color when exposed to UV light for a long time. The hardness, compressive strength and wear resistance of the material will not change.

Seleilte? series bearing tolerances

| diameter mm | post-press tolerance E10 | mounting aperture H7 | matching shaft diameter H9 |

| >0 ~ 3 | +0.014 ~ +0.054 | 0 ~ + 0.010 | 0 ~ - 0.025 |

| >3 ~ 6 | +0.020 ~ +0.068 | 0 ~ +0.012 | 0 ~ -0.030 |

| >6 ~ 10 | +0.025 ~ +0.083 | 0 ~ +0.015 | 0 ~ -0.036 |

| >10 ~ 18 | +0.032 ~ +0.102 | 0 ~ +0.018 | 0 ~ -0.043 |

| >18 ~ 30 | +0.040 ~ +0.124 | 0 ~ +0.021 | 0 ~ -0.052 |

| >30 ~ 50 | +0.050 ~ +0.150 | 0 ~ +0.025 | 0 ~ -0.062 |

| >50 ~ 80 | +0.060 ~ +0.180 | 0 ~ +0.030 | 0 ~ -0.074 |

| >80 ~ 120 | +0.072 ~ +0.212 | 0 ~ +0.035 | 0 ~ -0.087 |

| >120 ~ 180 | +0.085 ~ +0.245 | 0 ~ +0.040 | 0 ~ -0.100 |

Material Property Sheet

| Material Property Sheet | |||

| Conventional Performance | Unit | M1 | Testing Method |

| Specific gravity | g/cm3 | 1.46 | ASTM D792 |

| Color | dark gray | ||

| Dynamic friction/steel(dry) | μ | 0.08-0.15 | |

| Max.PV(dry) | N/mm2*m/s | 0.5 | |

| Max. rotating celocity(continuous) | M/s | 1 | |

| Max. rotating celocity(Short-time) | M/s | 2 | |

| Max. oscillating celocity(continuous) | M/s | 0.7 | |

| Max. oscillating celocity(Short-time) | M/s | 1.4 | |

| Max. linear celocity(continuous) | M/s | 4 | |

| Max. linear celocity(Short-time) | M/s | 5 | |

| Moisture absorption RH50/23℃ | % | 0.7 | ASTM D570 |

| Max.water absorption,23℃ | % | 4 | |

| Mechanical Performance | |||

| E-modulus | MPa | 7800 | ASTM D638 |

| Tensile Strength | MPa | 210 | ASTM D638 |

| Compressive strength | MPa | 78 | ASTM D790 |

| Max.static pressure of the surface,20℃ | MPa | 80 | |

| Shore hardness | D | 81 | ASTM D785 |

| Physical And Thermal Properties | |||

| Work temperature(continuous) | ℃ | -40/+130 | |

| Work temperature(Short-time) | ℃ | -40/+220 | |

| Thermal conductivity | W/m*k | 0.24 | ASTM D5470 |

| Linear coef.of thermal expansion | K-1*10-5 | 9 | ASTM D696 |

| Conductive And Flame Retardant Properties | |||

| Volume resisitivity | Ωcm | >1013 | |

| Surface resistivity | Ω | >1011 | |

| Flame retardance | HB | UL94 | |

+ MORE

-

-

Seleilte? Flanged Sleeve Bearings

Seleilte? flanged sleeve bearings are manufactured in a complex process for high performance engineering plastics.

READ MORE >>

-

-

Seleilte? Flange Bearings

The highly wear-resistant engineering plastics have a series of plastic bearings with excellent performances such as wear-resisting.

READ MORE >>

-

-

Seleilte? Sleeve Bearings

The seleilte? sleeve bearing is made of wear-resistant basic engineering plastics, fibers and fillers that are accurately combined to absorb high forces or loads.

READ MORE >>

-

-

Seleilte? Clamp Bearings

The Seleilte? Clamp Series is a rugged, wear-resistant bearing for medium loads that is suitable for bushings that pass through sheet metal.

READ MORE >>

-

-

Seleilte? Piston Ring

The Seleilte? Piston Ring is a family of PTFE tapes that replaces the PTFE tape with only one clamp guide ring for lifting elements.

READ MORE >>

-

-

Seleilte? Thrust Washer

The Seleilte? thrust washers are modified by adding active ingredients to high-performance plastics to reduce costs and protect connectors.

READ MORE >>